Though the fundamental technology has not changed, refrigeration has been witnessing exciting developments. Manoj John finds out what’s live and kicking in the cool space.

Nothing is permanent except change, said Heraclitus. Perhaps the Greek philosopher hadn’t presaged that refrigeration would defy that cosmic principle. Though the bakery and pastry industry has witnessed a revolution in recent years, overhauling all aspects of it, refrigeration is one thing that remained the same fundamentally.

“The underlying technology has not changed,” says Sunil Khanna. Several sights ranging from the wood-fired oven to dairy-based whipping cream are passé in the country’s thousands of bakeries. And many objects such as international breads and live bakeries have swept in the industry, even in smaller towns, in recent years.

Refrigeration could be the only constituent of a bakery that seems as untouched as ever. The permanence of refrigeration, however, begins and ends with its core purpose—cooling products and raw materials with a view to optimise their use.

What’s Trending

Outside of this, refrigeration has been undergoing many exciting developments. “Controllers offering UV cycles and humidity are innovations. So is remote access. Inverter technology is another major development,” adds Khanna.

The growth of the bakery and pastry industry in the past decade has been tremendously higher than that in the whole of the post- Independence India up till ten years ago.

This growth story has carried with it not just hitherto unseen products such as the French baguette and crème brûlée.

Pre-mixes, frozen products, international bakery chains and plush live bakeries in shopping malls were also part of the great Indian Bakery Odyssey.

Pillion-riding with it was growth in use of refrigeration. It is not just canned croissants or frozen breads that has increased the use of refrigeration. Increased popularity of frozen products has underscored the crucial position of refrigeration in a bakery set-up.

Frozen products come in various forms such as par-baked, preproofed and unbaked and fully baked but all of them require refrigeration.

“The only way to preserve confectionery products is by chilling or freezing. All products in the bakery and confectionery segment other than dry items need to be stored at safe temperatures,” says Khanna, mincing no words while underscoring the importance of refrigeration in the industry.

The market has witnessed a flurry of new refrigerators in recent times. The demand for nofrost refrigerators is on the rise. No-frost refrigerators are slowly becoming the standard equipment.

“Till seven years ago, people from outside the metro cities used to ask for the old type of refrigerators. Customers are also demanding equipment that maintains uniform air temperature inside the cabin” – Pranal Ganjawalla, director of MGRPO, Manufacturer

The Mumbai-based familyowned company has developed under-counter refrigerators without compromising on the capacity. “This is helpful for bakeries with smaller kitchens. There is a trade-off between kitchen space and the number of covers in cafes, and small refrigerators reduce kitchen space.

It is an innovation by us. We use smaller compressors to achieve this,” says Ganjawalla. Innovation knows no boundaries when it comes to innovation in refrigeration. IFI, a global brand in refrigerated display cabinets, recently launched an ice-cream pan which can store gelato, the Italian dessert, for six hours without electricity.

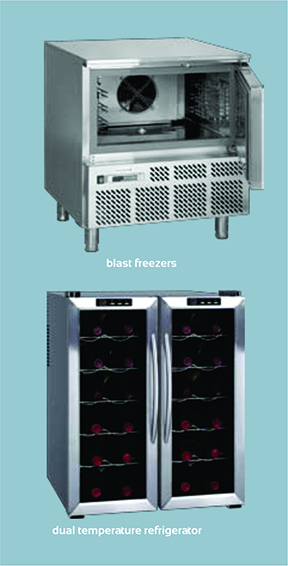

Stellar Gastronom, another international manufacturer, launched a range of blast freezers, open-chest coolers and dual temperature refrigerators. “Many innovative products are arriving in the market,” says Khanna who deals with these brands as well as Williams, UK. IFI, one of the world’s largest manufacturers in refrigerated display cabinets, produces Pozzeti Cabinets under a range called Panorama.

“No-frost cooling is another favourite nowadays,” Ganjawalla maps the trend. “Ventilated cooling and static cooling are in vogue in the Indian market,” Shailesh Patel, managing director, Riddhi Siddhi. Ventilated refrigeration contributes to food hygiene.

What’s Up

The eternal motto of “value for money” rules the roost as ever in refrigeration. As an investment of longer term, customers look for future upgrade of refrigerators. “Innovation and upgrade are foremost in the minds of customers. They are also keen on the quality of equipment,” says Patel.

The quality of after-sales service is also a key factor while selecting the brand. Customers are becoming more price-conscious at a time when inflation is heading for North. “Customers are price conscious. They are at the same time keen on the brand value of the product they choose,” says Ganjawalla.

William Soundarya Rajan, CEO of William Refrigeration, on the other hand, believes that in times ahead quality will assert itself in purchase decisions of bakers and pricing will take a backseat as an overarching determining factor.

Since refrigeration entails a considerable chunk of the total capital expenditure of a bakery unit, owners look for long durability of parts as well as the compressor.

Companies that presage the future dynamics of the market have a better chance to capture market share. “We prefer those manufacturers who will be able to fulfil our changing needs in future. Since the choice of the refrigerator brand is a wellthought decision, we prefer equipment with longer life,” says Ajai Sahni, a baker who supplies to corporate houses.

Customers are looking for chillers compliant with HACCP, a management system for food safety, with high level of intelligence built into the machines.

“They want smaller footprint of machines without compromising on the usable capacity. They also want high degree of reliability for a uniform stipulated temperature in the entire cavity. They want to spend less and have zerodown time to improve viability of their operations,” Khanna elaborates about his customers’ predilections.

Not just refrigerators but all the equipment in a bakery need specialised technical know-how to repair and replace parts. This is one reason customers prefer manufacturers with factories in India rather than distributors of imported equipment.

“Customers go for companies that have a pan-Indian service set-up with actual manufacturing set-up,” says Ganjawalla. MGPRO has a manufacturing facility in Silvassa, Western India, with automatic cutting and bending machines.

“People want equipment capable of performing in atmospheric temperature of up to 40° Celsius. They want products that perform in Indian conditions, which some of the imported equipment do not,” says Ganjawalla.

Beauty Full

The proliferation of live bakeries has also brought to life newer needs. The outer fittings of compressors, which were hitherto neglected, are important in a live kitchen that is constantly the cynosure of the customers’ eyes. Riddhi Siddhi gives thrust to the outer fittings which, ccording to Patel, will cut maintenance cost and lead to effective cooling.

Live bakeries necessitate a number of newer needs. They need retarder proovers, blast freezers and high quality display cabinets which can maintain 1° C temperature with zero condensation on the glass surface. Most manufacturers use good quality solid-surface material for finishing. Corian, manufactured by DuPont, is a favourite of most refrigeration companies for this.

The look and feel of the display shelves does enhance the appearance of the products inside it, which in turn has a bearing on the consumers. “Display shelves and cases make a big impact on the sales volumes,” says Sunil Khanna.

“Aesthetic aspects play a major role in the buying decisions of consumers. Presentation of the product is essential to its appeal,” says Patel, adding that this consideration nourishes the design of display shelves. “The demand from customers is that even the kitchen equipment should look beautiful,” says Ganjawalla.

Khanna says that display shelves should be designed in such a way that it does not subsume the products inside it. “The display shelves should not take away the attention from the products. The display cabinets should seamlessly blend with the décor of the outlet. They should be kept extremely clean and well-maintained lest the purpose is defeated,” says Khanna.

Eco’s Echo

It is global warming that has been setting the agenda for refrigeration technology globally for several years. “The need to mitigate the rate of global warming influences industrial refrigeration by restricting the choice of refrigerants available and making it important to improve efficiencies,” said S Forbes Pearson of Star Refrigeration Ltd, Scotland, at a global conference as early as 2008.

The amount of refrigerant charges is another concern for the industry. Environmental activists are worried on the degree of precaution relating to the amount of ammonia in the system. Conventional ammonia refrigeration systems are not designed with charge minimisation in mind.

It is possible to design systems that will operate with much lower refrigerant charges than conventional systems. Pearson had said that some of those include direct systems that will operate with less than one-tenth of the charge of a conventional system and secondary systems with less than one-hundredth of the charge of a conventional system.

High-efficiency refrigeration systems must be integrated in an overall efficient control system. Energy efficiency is a key for sustainable development. Energy efficiency is an endless objective in order to obtain more and to spend less. For refrigeration and heat pump systems, it requires not only to develop efficient components and equipment, but also to integrate equipment efficiently in larger systems. For buildings it is essential to think of efficient buildings as a whole and not only using efficient equipment.

Williams Refrigeration innovates on energy-saving methods. Its double pane glass helps avoid heat. This allows for compressors of smaller size that consume less energy. Electricity efficiency is a constant thrust of the research and development department of MGPRO too.

“Our products are hygiene friendly. We all know that India is not the best country is terms of hygienic conditions in food processing,” says Ganjawalla. Customers prefer refrigerators that do not have right-angled corners inside it for dirt to get accumulated. There are models without drains. There are also models fitted with self evaporating units and removable gaskets.

Refrigeration also plays a key role in hygiene. It slows the growth of bacteria. “Our refrigerator models are designed with a view to minimise health hazards,” says Patel about his company’s hygiene initiatives.

In future, the refrigeration industry is poised to witness bigger developments. It is today possible to control and indicate refrigerating systems remotely and in real time, thus making it possible to acquire data that would have been prohibitively expensive before. The data can be transmitted to any location, even across international boundaries. This has also allowed for variable-speed drives to be a practical possibility for large units.

In coming years, India’s already simmering bakery and pastry industry is expected to vibe with more and more innovations in the refrigeration area.