BakeryBiz, May-June, 2021

YUSUF PATANWALA

FOUNDER AND CEO

AUTOBAKE PRODUCTIONS

As a student of the bakery industry for the last 20 years, Yusuf Patanwala shares his experiences on how the industry has transformed in terms of automation and what kind of ‘future and fortune’ it upholds. In the second of a series of six articles, he gives an insight into the 4 most important aspects of bakery business.

The 1955 British classic war film “The Dam Busters” depicts the true story of how the ‘bouncing bomb’ developed by the British army to bust the enemy dams is executed with extremely high level of precision and planning by the carefully selected team of the RA F Squadron. The operation executed despite the numerous challenges of flying at just 18m above the sea level in absolute darkness is met with a sobering reflection that many aircraft flyers risked and lost their lives but for a purpose they all believed in.

This fantastic win by the brave soldiers of the army also gives insights for businesses who are out in the battlefield fighting to either survive or win and become leaders in their field of expertise.

Just like the 1943 “Operation Chastise” as they called it, every business needs to look into the 4 most important aspects of manufacturing:

1. Identifying and selecting the right team for the job.

2. Building an operation plan. The easiest way to lose a war is ‘chaos’.

3. Adopting the right technology as the ammunition to fight the battle in the market.

4. Smart procurement and use of bombs and bullets which are our raw material.

Let’s look into each of the above aspects in a little more detail.

Men

Manpower is the most important asset for any business. They are the people who believe in the work we do and commit to our business cause through their time, skills, talent and knowledge. We may be a small bakery with 10 people or a large organization of 1,000 people, the way we manage our team determines whether our most important resource becomes our asset or our liability. The hallmark of companies who excel in the art of men management is the following:

1. Leadership and Innovation: They are always ahead of their competition. They know and understand their markets and customers very well and are always ready to go the extra mile or bend backwards to accommodate the needs of their customers.

2. They identify, confront, discuss and solve problems very quickly: The best teams are very good in identifying and solving problems very quickly rather than waiting for them to turn into a big crisis before taking any action.

3. They take decisive actions and keep moving forward: One of the major cause for inefficiency and slow growth in any company is their inability to take decisions. This situation may arise from either lack of trust amongst the team and the management or lack of knowledge. The best teams are self-learners who are empowered to take decisions and at the same time made accountable for their actions.

Method

Once we have the right people on our team who know what needs to be done, the next important thing on the agenda is the HOW we can achieve our goals in the most efficient and effective manner? Hence, we need to design our systems and processes to take care of the following challenges that we face on a day to day basis:

1. The perishable nature of bakery goods which means we need to produce and deliver fresh products every day to the market.

2. Large variety of SKUs we need to produce on a daily basis.

3. Variation in demand as per week days, weekends, festivals, holidays, etc.

4. Problems in handling, packaging and distribution due to the delicate nature of bakery products.

5. Stringent norms related shelf life, food safety and hygiene

To be a quality and reliable supplier of bakery products in the market requires managing all the above challenges effectively on a daily basis. Without a well-designed production plan and system that takes care of all the above aspects, it is very difficult to build and grow a sustainable bakery business in todays time.

The various steps needed to design a good and effective production plan:

1. We need to start with understanding the needs and requirement of our customers. What products, when, where and how much we need to produce depends on this information.

2. Then we need to determine (using time and work study methods) how much time, materials, space and manpower does it take for us to produce the above products packed and ready for dispatch.

3. Based on the above, we need to calculate our daily shift timings and number of shifts / hours and manpower needed for various departments like the stores, mixing, baking, slicing, packing and distribution departments.

The proof of the pudding is in the eating! How well we design the above processes will determine the overall effectiveness of our business including its profitability.

Here are some of the benefits of good planning:

1. Customer gets the right products in the right quantity, at the right time and at the right place – ALWAY S! Means, our customers are happy!

2. We fulfil the quality and safety criteria related to our products. Means, we have peace of mind!

3. We utilise our resources like time, money, space, manpower, etc. effectively to produce the best quality products in least possible time and the lowest possible cost. Means, we are making good money!

Process Re-engineering, Six-Sigma, Kaizen, etc. are just some of the concepts worth pursuing to enable excellence and continuous improvement in this area of business.

Machines

Machines are an investment and not a cost. This mindset helps us to select the right machines that maximise the return on our investments.

Here are some ways in which machines can become a source of profit rather than a source of expense for our business:

1. Fuel / Power Efficiency: Fuel consumption is one of the major operating cost for a bakery. We need to look at machineries that help us in reducing our costs in this area.

2. Material Wastage: Non-uniform mixing, weight variation during scaling, over / under baked products, damages in handling and packaging are just some of the instances that lead to high operating costs that can be minimised using good quality machines.

3. Low Cost Automation: Adopting latest technology equipment for mundane and repetitive tasks or high skilled complicated jobs not only helps us in minimising the manpower costs but also reduces our dependence on skilled labour.

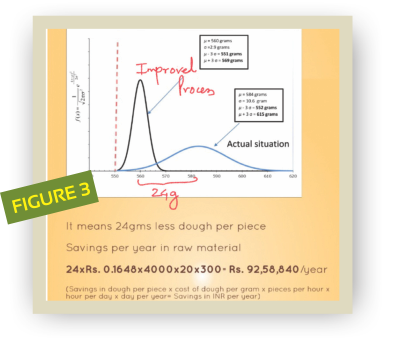

Total Productive Maintenance, Machine Utilisation Time, Low Cost Automation, etc. are just some of the concepts worth pursuing for excellence and continuous improvement in this area of business. A simple example of the kind of savings we can expect from fuel efficient ovens is shown in the chart (Figure 1) below

Material

The importance of raw materials is demonstrated by the simple photo (Figure 2) which shows how we have two totally different products with different kinds of flour while all the other parameters of the process, recipe and machinery remain exactly the same.

Besides quality, here are some other effects seen on shop floor when the specified quality criteria of raw materials are compromised:

1. Production delays due to increased processing time by either machines or the workers (inferior quality of potatoes significantly increase the peeling, chopping and boiling times leading to delay in production).

2. High materials wastage due to breakage and rejection of finished goods at various stages of production.

3. Loss of productivity and worker morale due to market failures, rejection and re-work.

Just-in-Time, Vendor Relationship Management, Supply Chain Management and Standardisation are just some of the concepts worth pursuing for excellence and continuous improvement in this area of business.

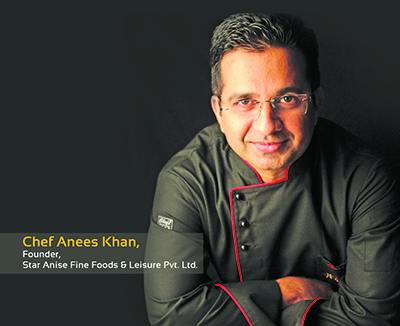

One simple example of how even a few grams of savings in dough weight during scaling process can result in huge savings in materials costs is demonstrated in the chart below (Figure 3).

To sum up the article, the 4Ms if executed smartly, based on the sound principles of business, helps us win the war by gaining customers, attracting talent, increasing our influence and building successful alliances with our suppliers and distributors in the market. If not, we will be left staring at the winners and wondering what went wrong with our business.

I hope there will important take-aways for all us from the above article. In the next article we will discuss how we can take our business to a totally different level with world class quality and productivity techniques. Till then, take care and be safe!