Packaging of bakery products is very important, because they are meant for use until long time from the day of its making. It plays a significant role in increasing shelf life, preventing mechanical damage, marketing, nutrition value and displaying food safety related warnings.

From the beginning, various methods have been used to seal and pack bakery products like twist tie, plastic tags, rubber bands. These traditional methods, however, faces a lot of criticism and problems from the time they came in use.

On the production side, these ways of sealing took a lot of time and demanded lot of effort and labor. Not only that, they had been a huge factor for less production. Since twist ties, plastic tags and rubber bands’ depends on the workers’ efficiency and skills, they cannot guarantee hundred percent food security and air tight environment for longer shelf life.

Technology is advancing and so is Packaging. The Tamper evident closure system is a beginning of new era in bakery packaging. The one of its kind, automatic packaging sealer promises to deliver and cater to all your needs.

Tamper Evident closure system, is an automatic sealer which uses a paper tape and an adhesive tape. The machine (InnoSealer) is an innovative invention that make perfect airtight seals every time within seconds and that too with just one go.

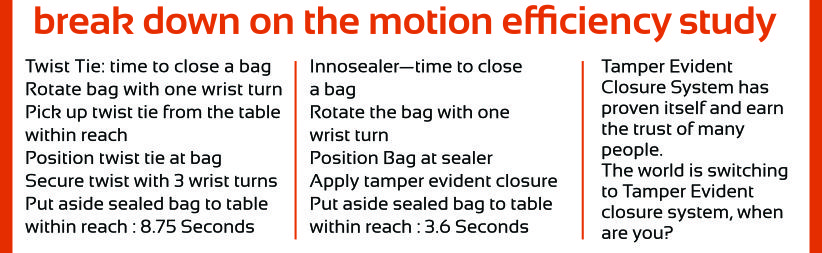

The process of sealing is quite simple yet effective. As shown (above image), the InnoSealer make packing a lot easier than ever before. There is more to it, with the innovative two tape system, you can repack and reuse the seal again. Hence, it also a great way of reducing wastage.

The tamper evident closure system provides high degree of security. Once sealed, the product can only be opened after tearing the paper tape, which makes it evident that the product has been used. That is why it is also called Twist and Pull sealing. Many companies have endorsed the Tamper evident closure system (TECS) as a means to eliminate the movements associated with Carpal Tunnel Syndrome (repetitive strain injury from using a twist tie). This makes for healthier and more productive employees.

The mess and wastage associated with wire ties i.e. sweeping the floor, picking out of the bread slicer and the amount of ties that are just wire with no plastic on them, is eliminated when using InnoSealer TECS.

Time Study Conducted by Nationally Recognized Testing House, July 2012 concluded that the InnoSealer generated in excess of 60% labour savings versus using wire ties.

10 Reasons to use Tamper Evident Closure System over Twist Ties and Plastic Tabs

1) gives authenticity & act as a consumer protection: As the only tamper evident closure; the Innoseal lets the customer know they are the first to open the bag (security of product). Thus, eliminates the risk of tampering & adulteration in between the supply chain.

2) ensures safety: The safety hazards of rusting & bare wire twist & tie and the danger of infant accidentally swallowing plastic tabs are eliminated when you choose the Innoseal as the bag closure. No metal or sharp edges are introduced into the food prep area.

3) product stays fresher & enhance shelf life: The Innoseal creates a seal that can be virtually air tight to keep the product fresher longer. It helps in maintaining the internal environment of the package.

4) lower cost & happy employees: Efficiency & cost reduction is delivered directly to the user. Many companies have endorsed the InnoSealer® as a solution to reduce the exposure to Carpel Tunnel Syndrome (repetitive strain injury) claims. HAPPY AND HEALTHY EMPLOYEES = MORE PRODUCTIVE EMPLOYEES.

5) preventing odor transmission, contamination& wastage reduction: The Innoseal® is a self-contained machine with no individual pieces to track, i.e. wire ties and plastic locks. This reduces risk of contamination exposure and excessive waste of material. Innoseal reduces landfill waste by more than 60% over twist & tie and 90% over plastic tabs by having a lower mass, lower volume closure. Thus the innoseal is the greenest bag closure system available today.

6) reusable & ease of handling: The innoseal closures enable the consumer to reuse the bag and the closure. It balances security of contents with ease of use, so that products are well protected but also easily to open.

7) logo printing, date coding and private branding: Print your own design on the refill paper. Print text, Bar codes and logos in quantities as you need. We have branding solution for all.

8) protection against chemical external influences: Chemical protection minimizes compositional changes triggered by some environmental influences such as exposure to gases typically oxygen, moisture (gain or loss), etc.

9) biological protection: It provides barrier to microorganisms, insects etc. thereby preventing diseases & spoilage of fresh fruits, vegetables & bakery products.

10) enhance product image: The innoseal closures enhance the product image by innovative differentiation of the product. The distinctive product image boosts sales in comparative market.