It’s not the first time that a bright Indian Institute of Management (II M) graduate has spurned well paying MNC jobs to pursue one’s own passion. Every year, we hear a few stories of IIM pass-outs setting up NGOs or starting mostly servic eoriented businesses.

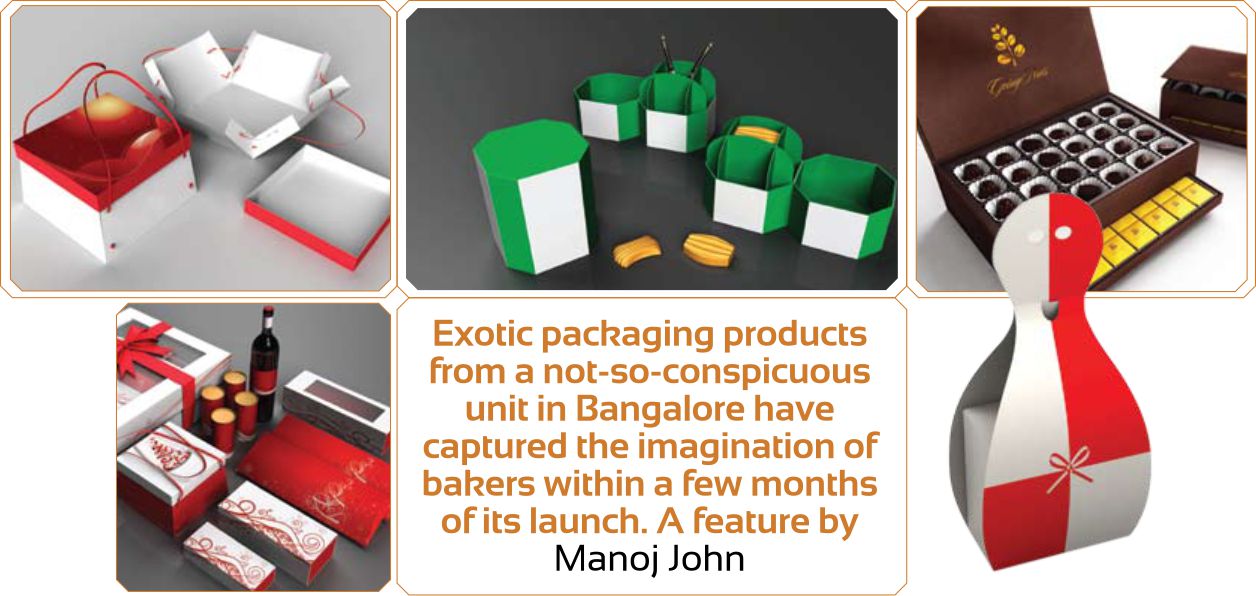

But the story of Gururaj Nayak is different. He chose to set up a conventional business—packaging—and yet did it in the most unconventional way. The packaging materials made at his start-up company PaperCats are a riot of creativity. Within a few months, “it has established itself as the industry standard in packaging,” as Nayak likes to put it.

The products are exclusively pre-ordered and manufactured in bulk and are not available through retail. PaperCats deftly plays to the upcoming rends in the packaging industry. It is a one-stop place where the customer walks in with a requirement and walks out with a product.

The shape of his flagship products can be transformed in many different ways, adapting them for multiple utilities. A pack for cake can be turned into a chocolate display stand. Another pack has no folds on the bottom or sides, which eliminates the possibility of the cake falling out in case of lax handling. In gifts, the cost of packaging is significant. Here PaperCats provides a unique value proposition. After the products have been used for its primary purpose of carrying bakery products, they can be reused as a pen stand, a lamp shade or an accessory case. Its unconventional approach is very likely to be in line with the norms of the future.

Its patented cake box is the first of its kind in the world. It can be stacked one above the other. It has a handle to carry, and has the best-in-class safety features to protect icing. This product is the best-selling product in the bakery category. “Packaging is not a print job. Neither is it a sole design job. It requires design acumen as well as 3D visualisation skills backed by a strong execution team, all beyond the usual,” says Nayak.

A look at his products culls the image of 3D animation models of the most ingenious class. Its design team comprises experts in 3D modelling, motion graphics, branding and communication, product designing and post production for ads and short films. “Once the model is ready, we take up actual prototyping and proofing which are 100 per cent accurate in size and 95 per cent accurate in aesthetics,” Nayak elaborates on the process at his design studio.

Beyond paper-based packaging, PaperCats works on materials as diverse as acrylic, MDF and leather. For a company as young as PaperCats, the team spends unusually long time and huge money on research to give birth to novel ideas. It has a successful patent filing and has more in the pipeline.

Artist-To-Techie

An engineering graduate, Nayak joined II M Calcutta to hone his management skills before putting together a creative team and venturing into his own business. “It was in Calcutta that it became clear to me that I would pursue entrepreneurship and the initial groundwork was laid for my first firm GoingNuts and subsequently PaperCats,” Nayak said, referring to his II M days.

“We are a family of artists and I vigorously pursued art right from the age of four. Hence my aesthetic sensibility developed well,” says Nayak. Understanding colours and making sense of complex three dimensional spaces come naturally to him. “If I trace the dots backwards, art, Going Nuts and IIM Calcutta are the three most defining factors for what PaperCats is today,” recalls Nayak. As Nayak was looking for better packaging done for his chocolate firm, he came across with the harsh reality that design process was indeed not the forte of printers. Nayak says, “Their designers were primarily editors. Then the design agencies whom I approached were bereft of the nuances of execution. Most of the shapes suggested were conventional.”

That is when he realised that there is a vacuum in the industry when it comes to specialised packaging manufacturing. He spent the next year moving from the printer to the retailer, from markets to industrial areas, and met with many exceptional individuals with diverse skills essential for the packaging industry. With them, he created a unique ecosystem of experts.

Packaging solutions were a natural extension of the chocolate manufacturing unit, GoingNuts, which was set up as a home-based business in November 2011.In March 2013, Nayak expanded his business into a captive design and packaging unit.

Today, the packaging brand PaperCats is a craze among discerning bakers in the South. “This helps us deliver the most personalised chocolate gifting solutions, unmatched and out of reach of the competition anywhere in the world,” says Nayak.

Its clients include some of the most reputed companies. “The response has been overwhelming. Everyone is looking for a change. People do want to see new things, new forms, and new shapes. The key is the value, and not the cost. Two kinds of packaging have been received well by the bakery industry. One is the sustainable, reusable packaging, and the other is our patented cake box,” says Nayak.

Nayak believes that the trend in packaging is sustainability. “It would act as the primary guidance for innovations in the future. There will be a small market for gift packaging with a fusion of materials, not restricted to paper,” says Nayak. The bakery industry is witnessing an increased awareness of food- grade packaging products. It is not necessarily just the paper, but adhesives and the manufacturing process too are also moving towards adopting food safety standards.

“The industry as an overall would see more specialised firms entering the field which is good for the industry as it would raise awareness and aid the development of better products. In future, this would enable more packaging focused design-cum-manufacturing entities to come up. As more specialists enter the industry more opportunities would be created,” predicts Nayak. At the same time, Gururaj realises that there are challenges involved in creating packaging solutions for bakeries. “There are two major challenges. The first is the perception of bakery owners that packaging is an obligation rather than a necessity. The second challenge is the low awareness with respect to food-grade materials,” says Nayak.

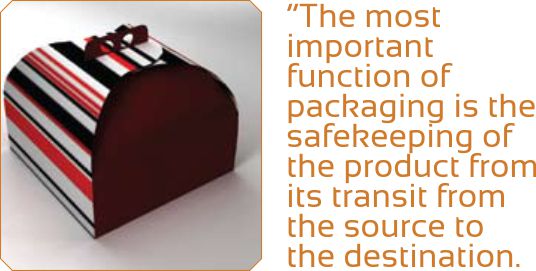

Bakeries view packaging as a major overhead. When someone buys a bakery product for consumption rather than gifting, the owners have to absorb the cost. Hence they attempt to go for the most economical option. “The most important function of packaging is the safekeeping of the product from its transit from the source to the destination. It is in this leg that the product is not monitored. The quality of the bakery product is judged at the stage when it is consumed. But most times the owners settle for the most economical packaging rather than the right packaging. If designed well, the right packaging should come to around 5 – 15 per cent of the cost,” says Nayak.

In the attempt to get the most economical packaging, both buyers and sellers alike try to cut corners and don’t adhere to food safety norms. Use of food grade materials and processes are compromised upon. “Here a well-planned food grade packaging would be marginally more expensive than a non-food grade product,” says Nayak.

Galloping Geek

Spotting an opportunity to expand his packaging unit, Nayak started supplying packaging to other bakeries. Today, he has more than what he can chew. But he has not bitten it off in haste. He prefers to build his business brick by brick.

“We have bootstrapped and so at a certain time in the near future we would definitely look for funding. At that time the expansion will be many-fold. Until then it would be a quick organic expansion on two fronts. First, packaging as a division is slated for multi-pronged growth. The other is the other design verticals within PaperCats,” says Nayak.

PaperCats is in talks with possible partners for expansion into the Middle East countries. “We are closing in on two different models, franchisee and self-owned businesses, for two of the upcoming Middle East markets. We would also expand in terms of product line by including boxes that involve a

combination of materials from paper to board, and acrylic to MDF. In all of these, the product quality and novelty would significantly be based on the research that we put in,” Nayak explains his plans.

The company is also looking for active expansion into other design verticals. The areas of focus are 3D animation, motion graphics, communication and branding, and product design. Of these 3D animation and motion graphics service would be available in the Middle East.“We are also working with some top artists to create world class art installations at their exhibitions,” concludes Nayak. By the end of next financial year, the staff strength will double to around 200, taking the company a notch ahead in its growth trajectory.