A report by Manoj John

A casual visit to a bakery kitchen will reveal a panorama of equipment imported from countries as varied as South Africa to Germany. The MacAdams and Koenigs have been adoring the backyard of bakeries for decades. If an American company has its way, there will be a sort of reverse phenomenon. Bakeries in those very countries will be increasingly baking their breads and biscuits in Indianmade machineries. That will be the Make- In-India dream come true.

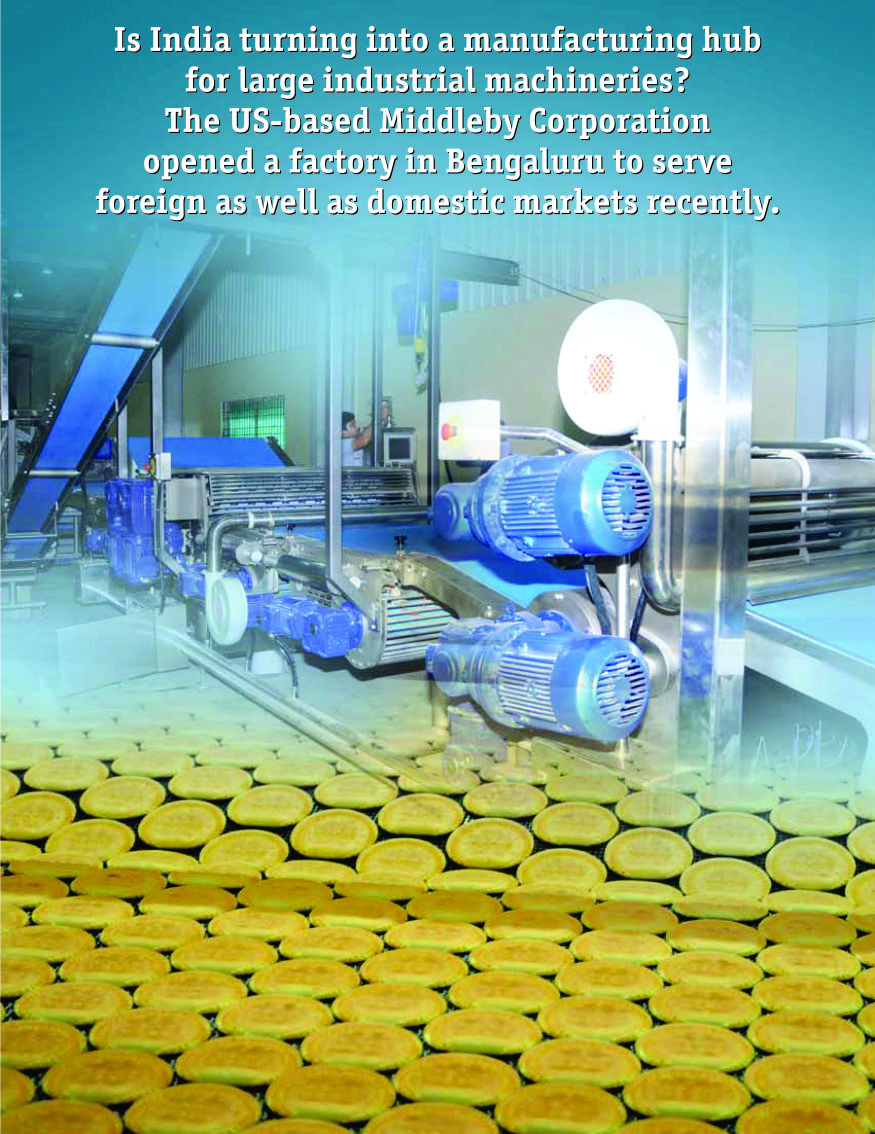

Illinois – based Middleby Corporation, a kitchen equipment manufacturer, has set off to make this dream come true with its launch of a multimillion-dollar factory in Bengaluru. This facility, named The Middleby Bakery Innovation Centre, will manufacture a broad line of equipment and export them to the West as well as sell in India. In Middleby’s overall scheme of things, India is not only a manufacturing hub but also a fast-growing market to reckon with.

The companies under Middleby fall under three verticals—industrial processing, commercial food service and residential kitchens. Food service is the biggest and the oldest of Middleby’s business verticals.

India has bilateral trade treaties with most countries to which Middleby intends to export its products made in India. Canada, one of its main markets, has no custom duty for bakery machineries made in India. Most developed countries have very liberal tax regimes for capital goods, often giving credit for the tax paid.

Middleby is currently on a spree to buy out companies worldwide to funnel its policy of inorganic growth. In the third quarter of 2017, the Group generated $28.6 million in sales from the companies it acquired recently.

With its acquisition of QualServ in August and Globe Food in October, the turnover accruing from the Group’s commercial food service equipment vertical is expected to increase manifold further. Earlier, the company acquired Burford (May 2017) and CVP Systems (June 2017) in an act which is expected to raise the near-term revenues from its food processing equipment vertical as well. The Middleby Corporation has more than 50 subsidiary companies under its fold.

The diversified machinery company had bought out Indian refrigerator manufacturer Celfrost a few years ago to cement its presence in the country. Cellfrost is more of a trading company which sells other brands in India.

Middleby’s efforts to upgrade its existing plants and set up new manufacturing facilities in developing markets such as India will boost its turnover further in the near term. At times, the company ends up buying companies that compete against each other. It nevertheless believes that acquisitions are aimed at giving the best solution to the customers. Middleby has, subsequently, not sold any company it has bought.

The Middleby Corporation is one of the top-ranking small companies in the world, winning several awards for innovation. Middleby is one of the oldest small companies in the US.

The Evolution

In the decades after the end of the American Civil War in 1865, the new nation was reconstructing itself. Entrepreneurship was promoted everywhere in the United States of America, and people were toying with newer and newer business ideas. The world economy itself had transformed by then with the emergence of large cartels and syndicates, and the convalescence of industrial capital and bank capital into finance capital.

It was at this peculiar juncture of world economy that a new economic entity was given shape by an enterprising duo in America each of whom carrying his name well into the present day. They were Joseph Middleby and John Marshall who joined hands in 1888 to manufacture portable ovens for supplying to bakeries. There started the story of The Middleby Corporation which today has multi-billion dollar market capitalisation at the stock market.

Twelve years later, Middleby sold his shares to Marshall whose descendants owned the company until a private company bought it over in 1970s. After changing hands all over again, the company was renamed The Middleby Corporation by the new owners in 1980s which now owns, among others, food service equipment brand Marshall.

That sums up the “primitive” history of Middleby. But the real history, for Middleby, began only after this. Reagan administration had turned over the US economic policy all of a sudden, freeing the industries from the shackles of Keynesian state control. Middleby increasingly looked onto the Third World to expand its manufacturing base, opening its first overseas facility in the Philippines in 1990s.

This was followed by a series of plant shutdowns across the US and company buyouts across the world without curtailing production capacity or product lines. New businesses were being acquired in the US as well as abroad. The buyout of Asbury Associates Inc., a Filipino manufacturer of food service equipment, was a turning point in the company’s path of inorganic growth. Asbury was to be the company’s export distributor for other countries except Canada where it owned its own set-up.

********************************************************************************************************************

Buyout powers existing brands: CEO Bassoul

The Middleby Corporation closed a deal to acquire Globe Food Equipment Company, a leading brand in slicers and mixers for the commercial foodservice industry, in October. Based in Dayton, Ohio, the company has approximately $50 million in annual sales. This is the latest buyout by Middelby. “Globe is a trusted leader in food preparation products known for performance, reliability, value, and reducing operator’s costs. The Globe family of products has been recognised as “Best in Class” by foodservice industry equipment dealers and complements the existing Middleby leading commercial foodservice equipment brands,” said Selim A Bassoul, chairman and CEO of Middleby Corporation.

“The addition of the Globe product offering enhances Middleby’s position for further expansion into the growing retail market segment. Additionally, through Middleby’s existing customer relationships and international infrastructure we anticipate Globe can realise further growth in new markets,” he added.

********************************************************************************************************************

Bodybuilding

By the middle of 2000s, The Middleby Corporation was a new incarnation of its old self with increase in income as well as stock valuation. All along the way, the company purchased many business firms. It bought out TurboChef, a loss-making manufacturer of pizza ovens, for $200 million which cemented its position in the food service equipment industry.

In 2012, Middeby bought over Spooner Vicars which specialises in large industrial production lines. Another significant growth point was the $380 million buyout of Viking Range in 2013, the largest in Middleby’s history. Aga Rangemaster, acquired in 2015, is among its latest assets. Its latest acquisition was Globe Food Equipment Company.

Brainwork

R&D is the thrust area within The Middleby Corporation. The VOIP hotline that connects various Middleby offices across the world facilitates easy communication among engineers. At the Bengaluru facility, for instance, engineers in UK and India seamlessly communicate with one another and work in tandem. An Indian engineer can resume the work started by a UK engineer and vice versa. This robust communication system adds immense value to the design and manufacturing process.

The highest level of automation is at work at Middleby. In the whole of the factory area, the only place where human presence can be seen is the packing area. The back-end stages are fully automated. There are certain aspects where analogue signals are inevitably required but the rest of the automation completely hinges on digital technology. Operators can watch details online in real time.

Innovation is in the DNA of Middleby. Even from one line to the next line, there is innovation. Innovation is not just about the layout and arrangement of machines. Innovation at Middleby is inextricably linked with performance and the humanmachine interface. The company has lined up many releases in the coming months from its Bengaluru facility.

The Middleby India team with foreign dignitaries during the opening of the company’s factory in Bengaluru.

BIC will help cross-pollination of ideas: Subramaniam

The newly opened Bakery Innovation Centre of Middleby in Bengaluru will help foster new ideas besides being a major manufacturing hub in Asia, said Balaji Subramaniam, managing director of Spooner Vicars.

Bengaluru is the ideal place for Spooner Vicars’ manufacturing facility, said Subramaniam. Spooner Vicars is part of The Middleby Corporation. Speaking on the sidelines of the inauguration of BIC recently, he said Middleby is in India for a long haul.

This is Spooner Vicars’ the first full-size manufacturing centre in India. The Bengaluru factory, called Bakery Innovation Centre, which has been producing world class equipment for almost 10 years, now boasts of a dedicated hygienic testing space fitted out with the new VORTEX mixer and 1.2m wide APEX 400 laminating and sheeting line complete with a 3-zone hybrid oven 28m long. Spooner Vicars is one of the world’s leading baking equipment manufacturers.

Subramaniam said Bengaluru is still a smaller city compared to other metropolitan cities in the country and provides advantages in terms of logistics movement. “It is not true that Bengaluru is not the place for capital goods manufacturers. This city is home to several heavy goods manufacturers such as Hindustan Aeronauticals Ltd and BEML.” Subramaniam said.

“Besides the private and public sector blue chip companies, there are several small and medium sized enterprises in the vicinities to which Middleby can cater to,” he said. Subramaniam said biscuit consumption is very low in our country as compared to the developing countries, adding that the scenario is changing.

The Bengaluru facility can also act as a platform for exchange of ideas, said Subramaniam. Middleby has several partners such as ingredient manufacturers and organisations such as the American Institute of Baking (AIB). They can hold workshops and training sessions at the Bengaluru facility.

Balaji Subramaniam, MD, Spooner Vicars

“There will be cross pollination of ideas that will improve the standards for everyone. There are many things that are not intellectual properties which can be shared for the betterment of everyone. Prospective customers also can come and try a certain recipe before they invest in a full line of machinery,” said Subramaniam.

Large machineries such as bread or cookies lines are meant to last 30 – 50 years. “One of our customers owns our equipment since 1970s. They just added 13 metres of extension since they did not want to get rid of the machine. That is the kind of longevity our equipment has,” elaborated Subramaniam. Another company from Canada has till now bought 12 Spooner Vicars machines, which shows the commitment by the company’s customers.

The grand opening ceremony was attended by major Indian biscuit producers as well as a strong international contingent including visitors from China, Canada, Egypt, USA, Philippines, New Zealand, UK, Spain, UAE, Thailand, Malaysia, Singapore, and Sweden.

Several dignitaries also attended the event. JN Kushawaha, president of the Society of Indian Bakers (SIB), in his speech, underscored the need for standardisation in the Indian bakery industry. Pizzas and burgers have standard sizes measured in inches but Indian food products do not have standardisation. Kushawaha also made a strong case for modernisation of the industry.

Following the speeches by dignitaries, the test line was fired up by remote keying by VIPs. A number of Marie batches were mixed, laminated, sheeted and baked under the gaze of the international visitors.

The new testing centre will be used by both national and international biscuit manufacturers for recipe and new product development, ingredient substitution trials, training and seminars, as well as being a showcase for Spooner Vicars ongoing launch of state-of-theart biscuit production equipment such as the VORTEX mixer and the APEX 400 laminating and sheeting line.

Separate desktop presentations were given by AL Rollers (UK), Sveba Dahlen, Burford, Stewart Systems, Axis Automation, TNA (Arcall), Ammeraal Beltech India, Rockwell Automation, Festo India, ESA Manufacturing, Keyence India and Mettler-Toledo India.