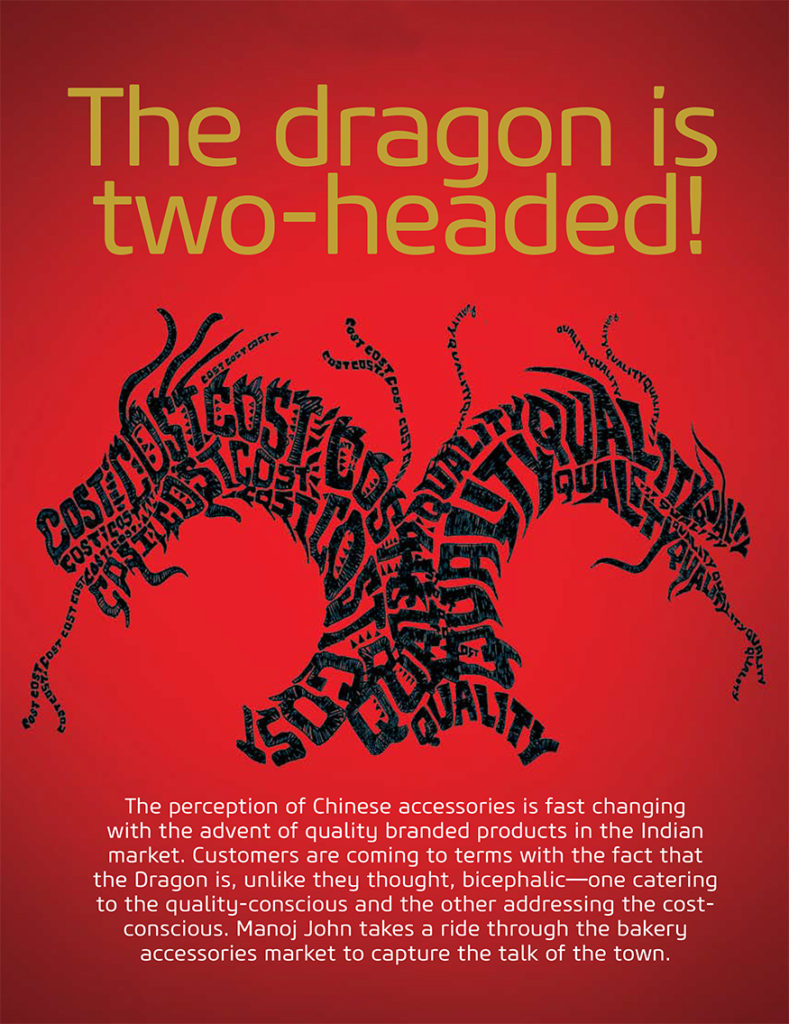

In the Indian market, everything from China is usually looked down upon. Bakery accessories are no different. In spite of this low perception, cheap and low-quality accessories from the neighbouring country have flooded India in recent times, sources close to the development say.

The market for accessories for the restaurant and catering segment, which is growing at 15 per cent per annum according to a random survey of business owners conducted by Bakery Biz, is never satiate with Chinese products. The market is growing partly because customers are on the lookout for newer and newer accessories in line with the changing demand. Bakery is one of the thrust areas of this demand.

“Everyone is looking for something new when they go for purchase. Customers want something new in terms of the product, technology and finishing,” says Sagar Sachdeva, proprietor, Butler Mart.

This puts the manufactures under constant pressure to innovate. Chinese companies are never tired of innovation, in tune with the newer needs of the industry, which accounts for the dominance of their products in the Indian market.

With every new product innovation in bakeries, the need for commensurate accessories also arises. Cakes in square shape are, for example, in vogue among consumers at present, leading to more demand for the necessary accessories. There are new patterns such as texture cakes that have found their way to the market lately, which, in turn, necessitates adequate moulds and boards.

Alongside the rise in demand for new products, the bakery industry is adopting large-scale mechanisation. This denotes the biggest transformation in the history of Indian bakery industry which overly lies in the disorganised sector.

“The Indian bakery industry is fast undergoing mechanisation. Installation of industrial lines is on the increase in recent times. At the retail bakery level too, the tools at work have changed. There is a 180 degree change in the last four to five years.

Automated tools are taking the centre-stage. Electric cake cutting is the norm of the day.

Icing is done by machines. Computerised printing is fast catching up as a craze among consumers,” says Imran Hamadani, director at Arife, one of the first Indian companies to deal with bakery accessories, adding that “the influx of Chinese products is a necessary consequence of the growth of the country’s market.”

“There are, however, good as well as bad products coming from China,” he clarifies. And this is a point that is underestimated by the Indian people in general including the most discerning businessmen.

There are several factors that are fuelling the flurry of Chinese products into India.

That there is no regulation of quality standards for baking accessories comes in handy for the Chinese companies that manufacture low-quality products. “Unlike in Europe, there are no standards for bakery accessories in India,” says Hamadani.

Neha Agarwal, home baker, also vouches that there are good quality Chinese products.

“I have been using Chinesemade accessories for quite a long time, and my products turn out well. It’s a myth that Chinese products are all bad. One needs to carefully pick the products from the market, whether Chinese, Indian or European,” says Agarwal.

Rajesh Jain, director, Ihomez/STEC, on the other hand, takes a studied approach.

“All Chinese products cannot be bundled together under one quality standard. There are different types of qualities among Chines products. There are highquality branded accessories as well as low-quality cheap items coming from China. It is up to the bakery owners to decide what product they want to use,” he says.

Sushil Gadgil

“People used to wrap bakery products in newspapers in olden times. Now they are aware of the health hazards of the printed ink and turning to food-grade packaging materials,” – Sushil Gadgil, ECOPACK

The Indian market players are ambivalent on the lack of standards not only for imported accessories but also for domestically manufactured ones. While those who are quality-conscious are worried over the lack of standards, manufacturers at the low-end are finding it as a blessing in disguise. That is because they can pass off accessories made of non-food grade materials as acceptable products.

Sushil Gadgil from Ecopack believes that consumers are becoming more and more conscious of quality and hygiene. “People use to wrap bakery products in newspapers in olden times. Now they are aware of the health hazards of the printed ink and turning to food-grade packaging materials,” says Gadgil.

“There are no standards as such in the accessories market. It is a huge market with a turnover of Rs 1,000 crore. It all depends on what type of accessory and what category it belongs to. It also poses the danger that a company can use any type of material, including non-food grade, for making accessories that come in contact with the food,” says Sachdeva.

This opens up possibilities for Chinese as well as Indian companies to use nonfood grade material, posing health hazards. This assumes significance in the context of reports that Chinese-origin toys contained toxic chemicals.

Neha Agarwal

“I once used silicon cake mould, which turned whitish inside after baking. It is really hard to differentiate quality material in a market where there are no official specifications,” says Agarwal.

Unlike Chinese products, European goods have a general acceptability among customers built over many years of goodwill. “The endproduct from Europe has good finishing. It is the price factor that makes people sway over to the Chinese products,” says Jatin Gutt, director, Radha Krishan & Sons, a pioneer in bakery accessories. “There is an increased focus on retail outlets nowadays when it comes to accessories,” says Gutt, adding that his company deals with more than 55 brands.

Arup Dastidar, senior chef, also agrees that European products have high quality. At the same time, according to him, a good craftsman can chisel out great products with any accessories.

“Accessories must enhance your products. That is the end purpose of any accessory,” says Dastidar.

Besides retail, the home segment also is registering a year-on-year growth of not less than 15 per cent. This segment, comprising home bakers who are involved in commercial supply as well as amateur bakers who bake for their family’s consumption, is one of the biggest drivers of accessories market. This is evident from the crowd of home-oriented bakers thronging trade shows such as the annual Bakery Business.

Tayyeb Dhariwal

“The sales of cake moulds for domestic purpose have gone up. We are now into mass distribution of moulds for cakes, jelly, bread and hotdogs. The designs for cakes and pastries are multiplied. Another trend is paper cups for muffins and cheese cakes,” Tayyeb Dhariwal from Rolex summarises the market trend.

The show-stopper in the accessories market in India is, as always, lack of quality standards. “Good companies, especially those from the West, adhere to NSF standards. The label on European products show NSF-approved, which implies it is worldwide approved as food-grade. The government of India has no regulatory control over it,” says Sachdeva.

Unlike imported food products, which are regulated by Food and Drug Administration (FDA) and Food Safety and Standards Authority FSSAI), bakery accessories are not subjected to any regulation by the government for its quality standards. Most of the Chinamade accessories are low-quality, according to Sachdeva.

Chinese products can be at time deceptive. “Some of the Chinese products look good from outward but they could be of low quality. The tin plates, for example, are not food-grade. It must be borne in mind that the Chinese manufacturers are not answerable to anyone. It gives them a free hand to be occupied only with the number game,” says Tayyeb Dhariwal from Rolex.

Indian-made accessories are no different, according to old-time players in the industry. “There was no system of MRP in places like Crawford Market in Mumbai, which was the hub for bakery accessories, earlier. Things have undergone a drastic change since those days,” explains Jain who also urged for some kind of regulation of quality standards.

“Accessories” is not a homogenous term. They are as variegated as kitchen tools to display shelves. The primary level is the accessories used for preparation of the food item. This is one area that needs utmost attention while selecting since these accessories come in direct contact with the raw materials and finished product. There is a high degree of health hazards.

The accessories used for serving are also equally sensitive since these also come in contact with the eatable products. Yet another category is packaging materials. There are many items in this category also, such as the cake board, which have physical contact with the food product. Sturdiness and aesthetics rule the roost in this category.

As for accessories for display, the visual appeal is the most important factor that determines purchase decisions. “Moulds, designs and colours also are considered accessories,” Sachdeva elaborates the scope of bakery accessories.

Chinese products can be at time deceptive. “Some of the Chinese products look good from outward but they could be of low quality. The tin plates, for example, are not food-grade. It must be borne in mind that the Chinese manufacturers are not answerable to anyone. It gives them a free hand to be occupied only with the number game,” says Tayyeb Dhariwal from Rolex.

Indian-made accessories are no different, according to old-time players in the industry. “There was no system of MRP in places like Crawford Market in Mumbai, which was the hub for bakery accessories, earlier. Things have undergone a drastic change since those days,” explains Jain who also urged for some kind of regulation of quality standards.

“Accessories” is not a homogenous term. They are as variegated as kitchen tools to display shelves. The primary level is the accessories used for preparation of the food item. This is one area that needs utmost attention while selecting since these accessories come in direct contact with the raw materials and finished product. There is a high degree of health hazards.

The accessories used for serving are also equally sensitive since these also come in contact with the eatable products. Yet another category is packaging materials. There are many items in this category also, such as the cake board, which have physical contact with the food product. Sturdiness and aesthetics rule the roost in this category.

As for accessories for display, the visual appeal is the most important factor that determines purchase decisions. “Moulds, designs and colours also are considered accessories,” Sachdeva elaborates the scope of bakery accessories.